Case study

Ski Boot

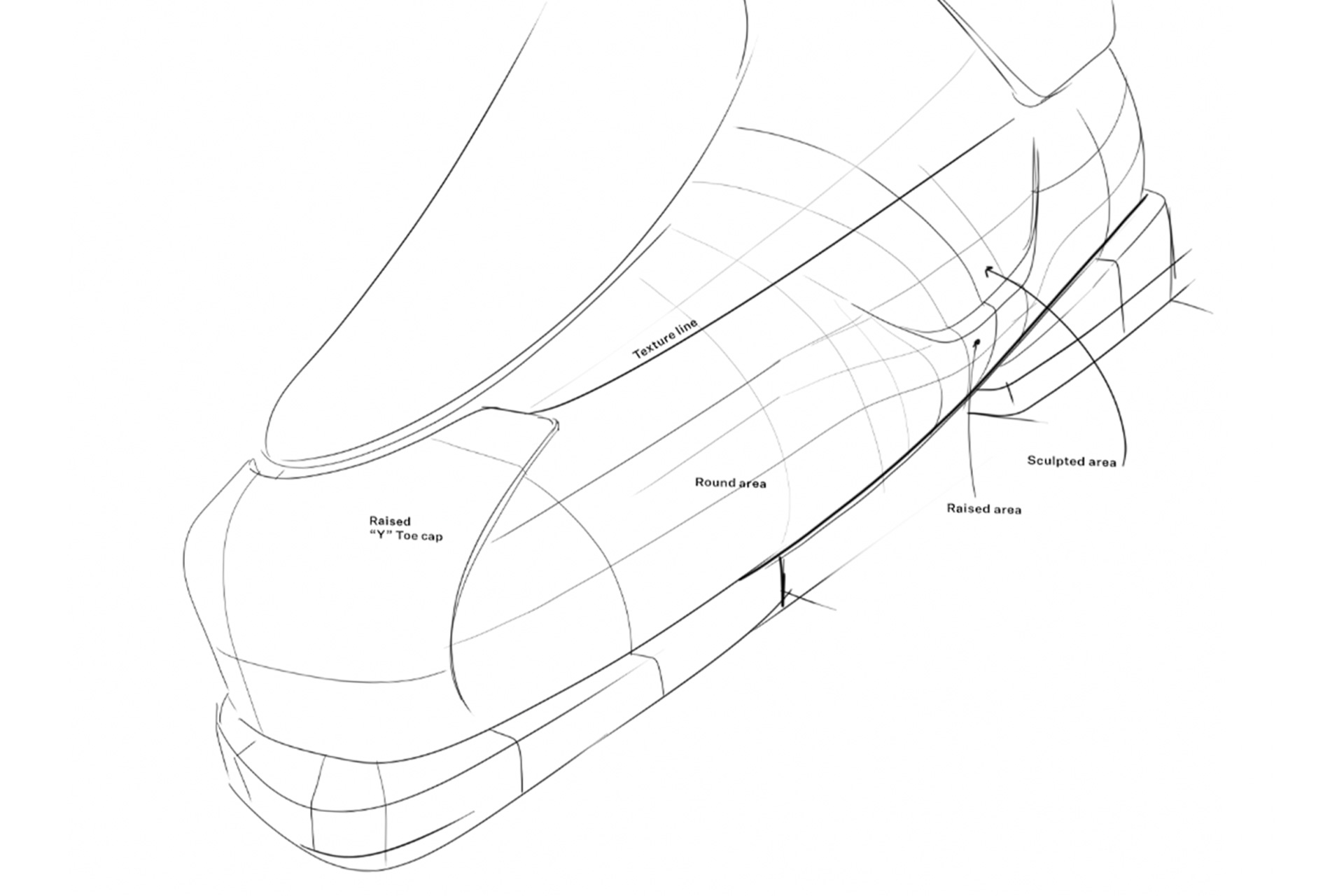

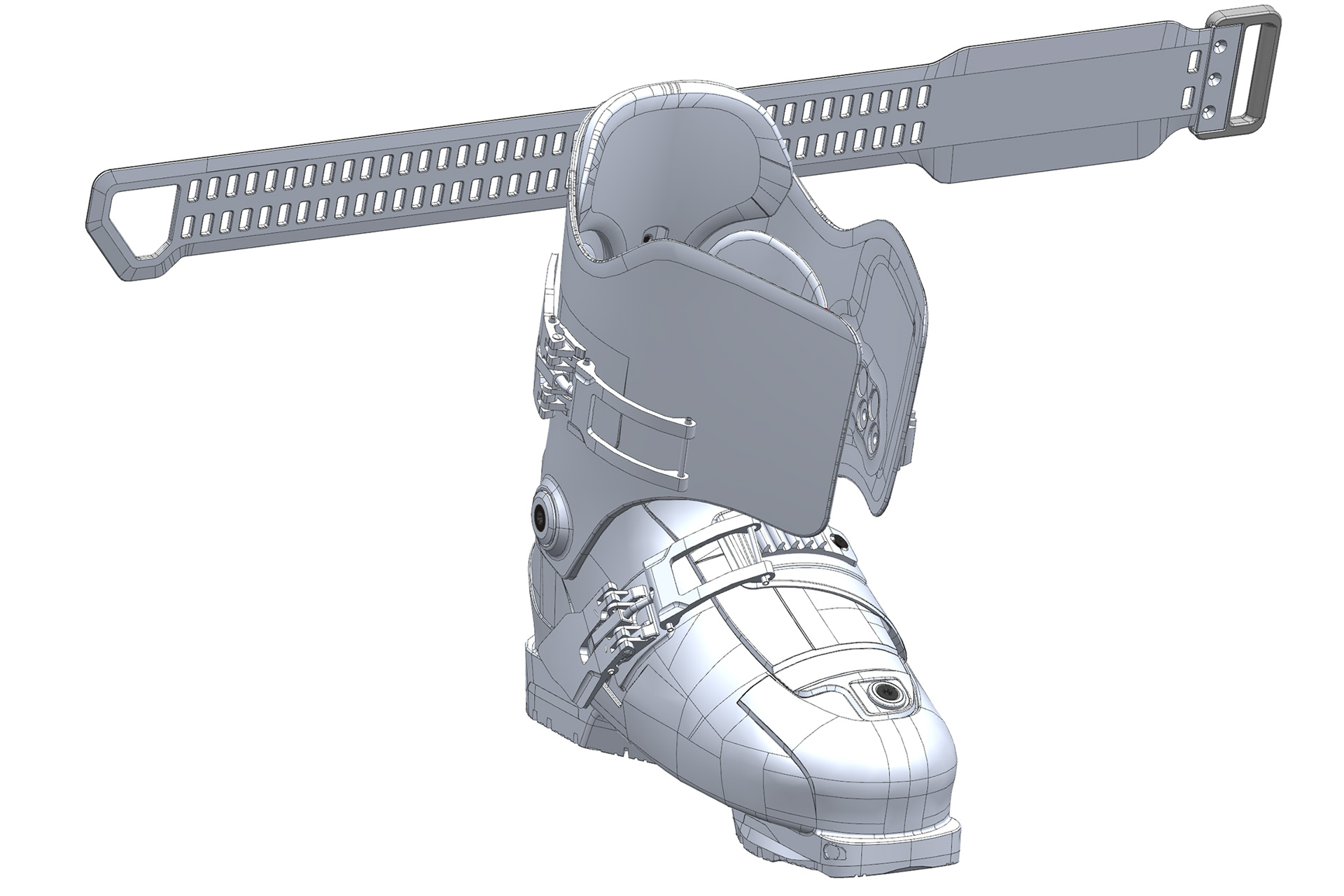

We developed a complete ski boot system, handling both the hard plastic shell components and the soft inner boot construction. The project involved comprehensive 3D design and prototyping work to optimize the boot’s structural elements and ensure proper fit integration between all components.

Both hard and soft components underwent specific testing protocols to validate their performance characteristics. The plastic shell was subjected to conditioning tests that evaluated its response to humidity and temperature variations, followed by impact testing to assess structural integrity under stress conditions. The inner boot system was tested through conditioning protocols to verify its performance consistency across different environmental conditions.

The development process covered the complete product lifecycle from initial 3D modeling through prototyping phases to final mass production and assembly lines. From the earliest design stages, we integrated Life Cycle Assessment considerations to guide material selection and manufacturing approaches, working to reduce carbon footprint without compromising the performance and durability standards expected in demanding alpine environments. Throughout each phase, we maintained continuous collaboration with the client, incorporating their feedback and requirements to refine both the plastic shell and inner boot systems before proceeding to the next development stage.