Case study

Neck Protector

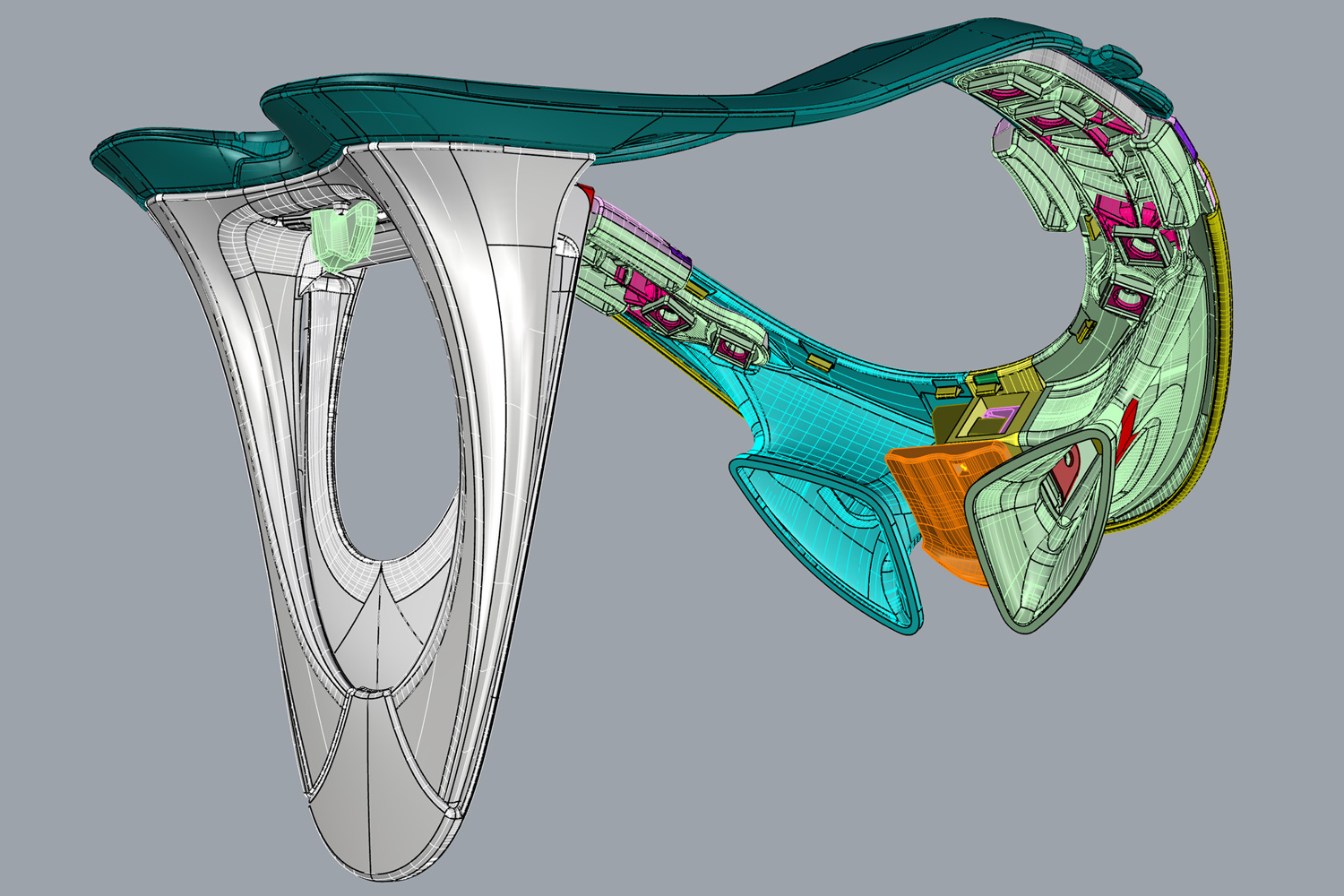

We managed the development of key components for this CE-certified neck protector for motocross and offroad motorcycling.

The plastic structure was engineered using an advanced carbon polymer composite designed to withstand high-impact forces. We handled the complete 3D design and manufacturing of this rigid component to ensure it could effectively manage the energy loads typical of off-road riding conditions.

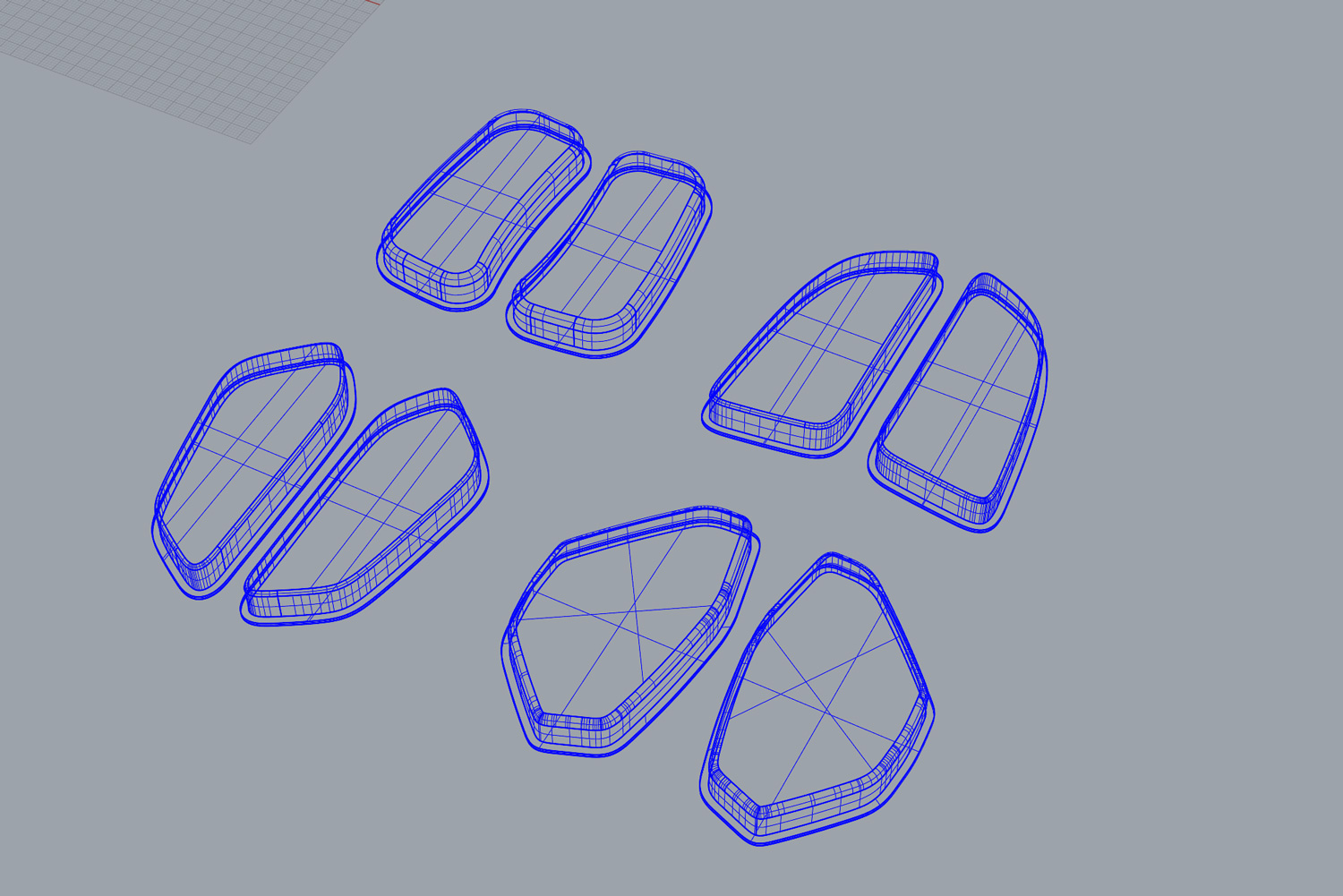

The ergonomic-protective padding was developed in EVA material using our thermoforming expertise. We handled the complete design and in-house production of these pads to ensure they worked effectively with the plastic structure while providing the necessary comfort and protection.

We carefully selected and integrated multiple ingredient brands, including FIDLOCK’s innovative magnetic fastener technology, to create a comprehensive protective solution while maintaining strict project confidentiality throughout the development process.

Throughout the development process, we conducted laboratory testing to validate performance and gathered continuous feedback from the client. This iterative approach allowed us to refine both the structural design and the padding configuration based on test results and client input, resulting in refinements to the final production design.