Case study

Back protector

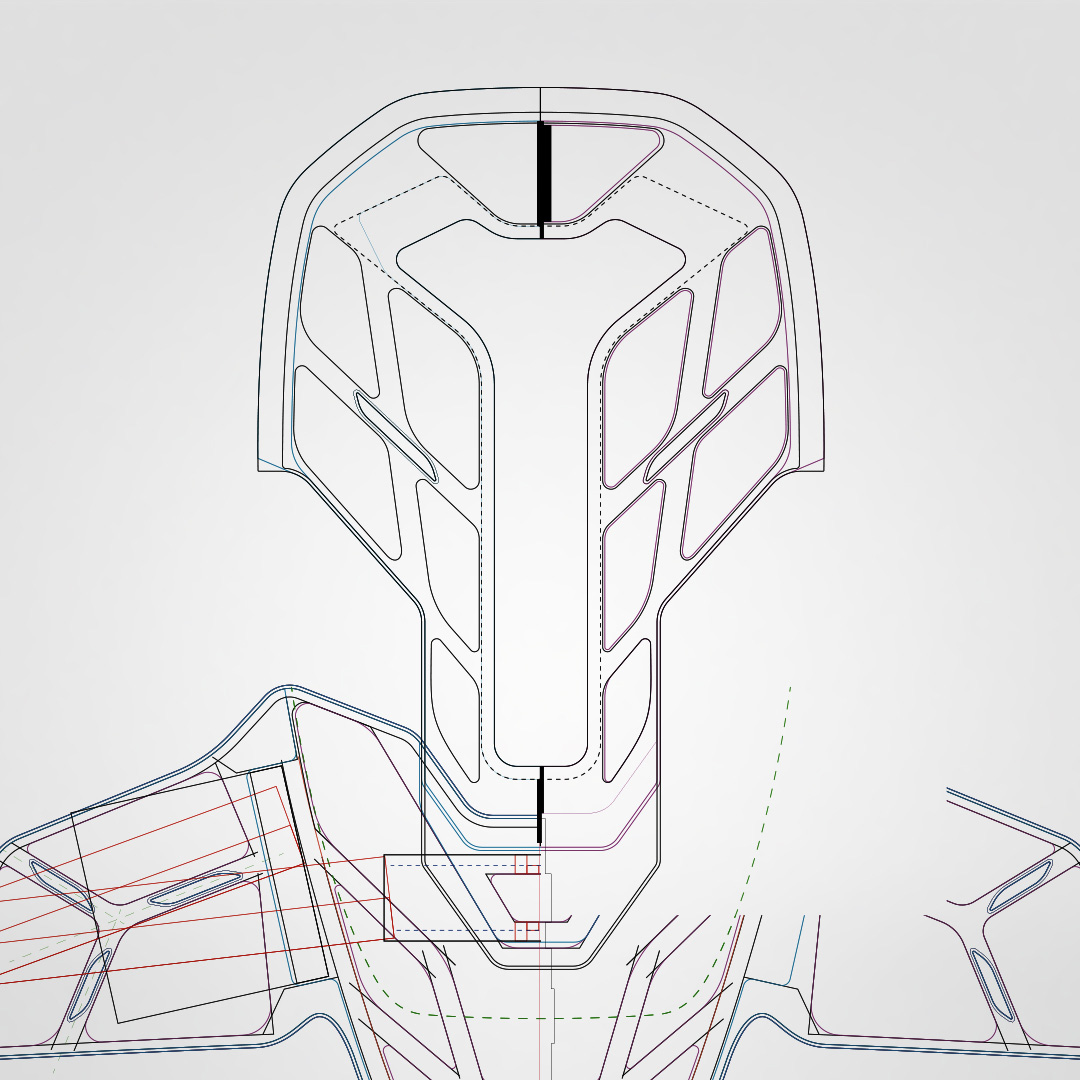

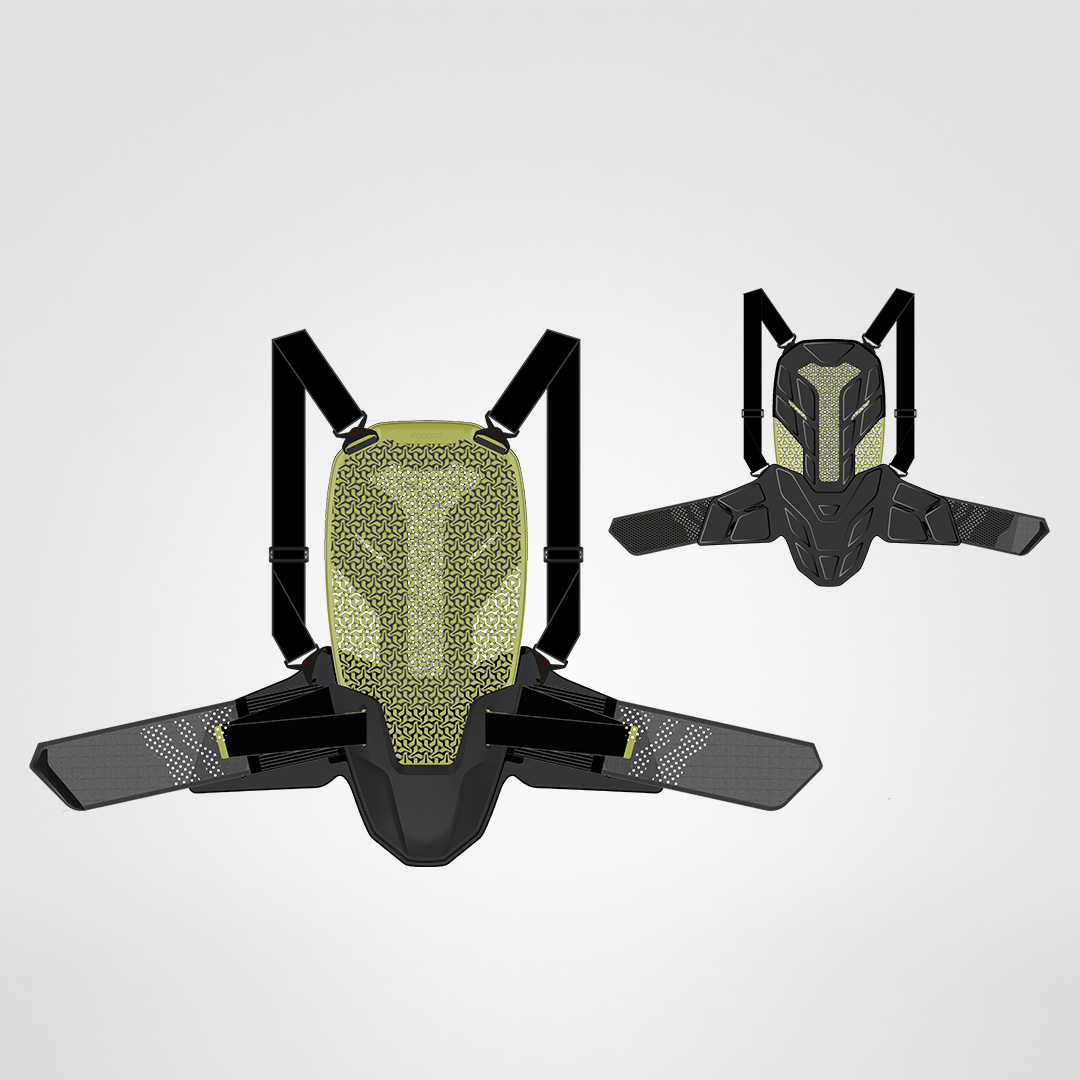

We developed this removable back protector from initial concept through to mass production, managing the complete design and manufacturing process.

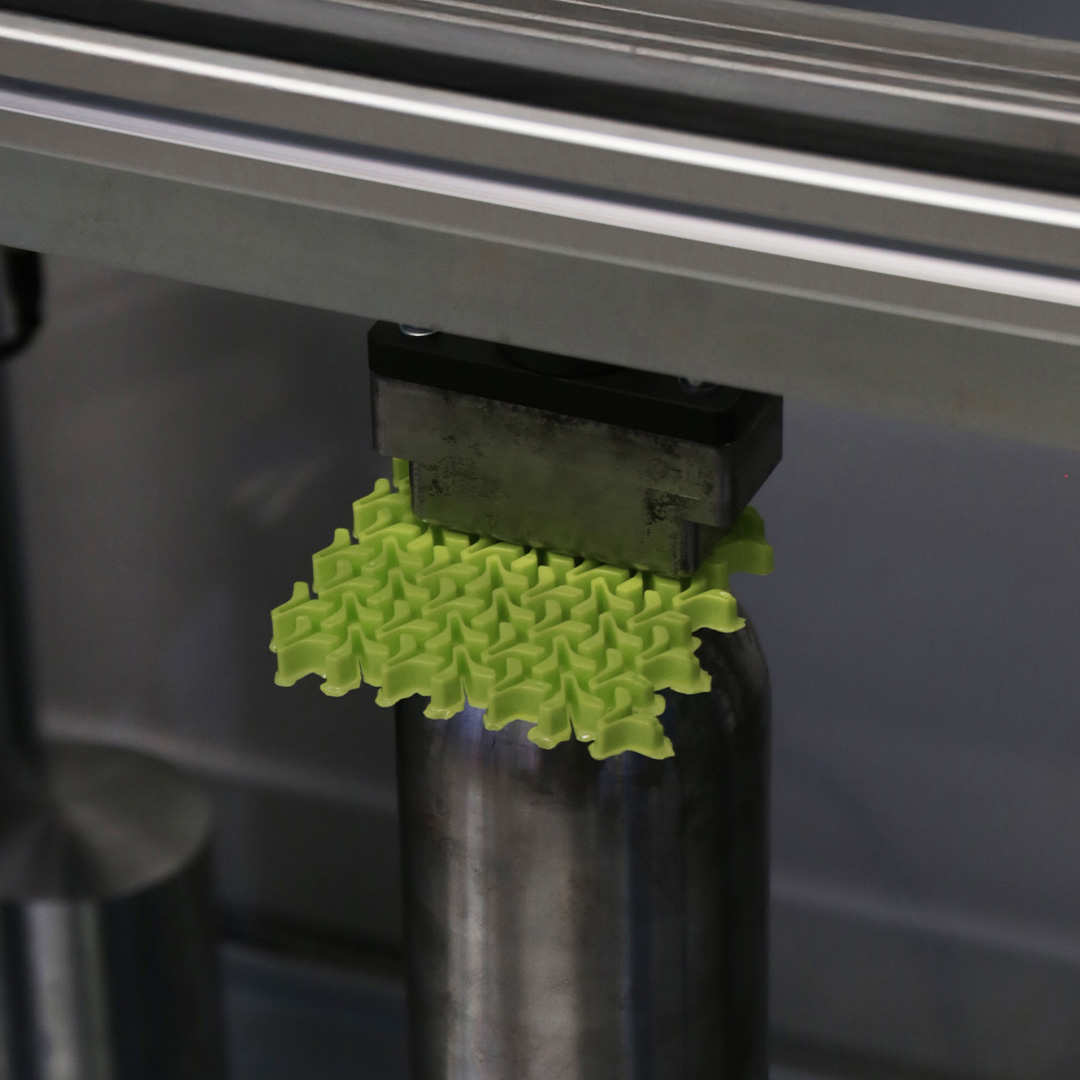

The protective shell was engineered in recyclable PE and manufactured through injection molding. The component was then subjected to rigorous impact testing to verify compliance with EN1621 standards.

The supportive harness system was created by integrating textile components with the rigid shell using thermoforming and stitching processes. This required coordinating multiple manufacturing techniques to achieve an ergonomic fit that combined the soft support structures with the hard protective element.

Each component underwent testing before final assembly. The entire project was managed internally, from CAD design through prototype development to production tooling and mass manufacturing, maintaining oversight of every phase of the development cycle.